Poppet Valve (MA)

Libraries:

Simscape /

Fluids /

Moist Air /

Valves & Orifices /

Flow Control Valves

Description

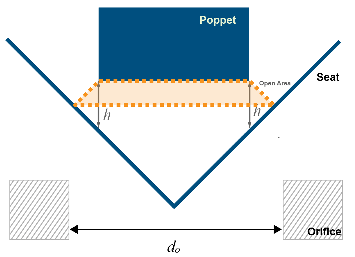

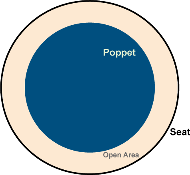

The Poppet Valve (MA) block represents an orifice with a translating ball that moderates flow through the valve. In the fully closed position, the ball rests at the perforated seat, and fully blocks the fluid from passing between ports A and B. The area between the ball and seat is the opening area of the valve.

The flow can be laminar or turbulent, and it can reach up to sonic speeds. The maximum velocity happens at the throat of the valve where the flow is narrowest and fastest. The flow chokes and the velocity saturates when a drop in downstream pressure can no longer increase the velocity. Choking occurs when the back-pressure ratio reaches the critical value characteristic of the valve. The block does not capture supersonic flow.

Cylindrical Stem Poppet Opening Area

The opening area of the valve is calculated as:

where:

h is the vertical distance between the outer edge of the cylinder and the seat, indicated in the schematic above.

θ is the Seat cone angle.

ds is the Stem diameter.

Aleak is the Leakage area.

The opening area is bounded by the maximum displacement hmax:

For any stem displacement larger than hmax, Aopen is the sum of the maximum orifice area and the Leakage area:

For any combination of the signal at port S and the cylinder offset less than 0, the minimum valve area is the Leakage area.

Round Ball Poppet Opening Area

The opening area of the valve is calculated as:

where:

h is the vertical distance between the outer edge of the cylinder and the seat, indicated in the schematic above.

rO is the seat orifice radius, calculated from the Orifice diameter.

rB is the radius of the ball, calculated from the Ball diameter.

Gsharp is the geometric parameter:

Aleak is the Leakage area.

The opening area is bounded by the maximum displacement hmax:

For any ball displacement larger than hmax, Aopen is the sum of the maximum orifice area and the Leakage area:

For any combination of the signal at port S and the ball offset that is less than 0, the minimum valve area is the Leakage area.

The opening area of the valve is calculated as:

where:

h is the vertical distance between the outer edge of the cylinder and the seat, indicated in the schematic above.

θ is the Seat cone angle.

Gconical is the geometric parameter: where rB is the ball radius.

Aleak is the Leakage area.

The opening area is bounded by the maximum displacement hmax:

For any ball displacement larger than hmax, Aopen is the sum of the maximum orifice area and the Leakage area:

For any combination of the signal at port S and the ball offset that is less than 0, the minimum valve area is the Leakage area.

Valve Parameterizations

The block behavior depends on the Valve parametrization parameter:

Cv flow coefficient— The flow coefficient Cv determines the block parameterization. The flow coefficient measures the ease with which the moist air can flow when driven by a certain pressure differential.Kv flow coefficient— The flow coefficient Kv, where , determines the block parameterization. The flow coefficient measures the ease with which the moist air can flow when driven by a certain pressure differential.Sonic conductance— The sonic conductance of the resistive element at steady state determines the block parameterization. The sonic conductance measures the ease with which the moist air can flow when choked, which is a condition in which the flow velocity is at the local speed of sound. Choking occurs when the ratio between downstream and upstream pressures reaches a critical value known as the critical pressure ratio.Orifice area based on geometry— The size of the flow restriction determines the block parametrization.

The block scales the specified flow capacity by the fraction of valve opening. As

the fraction of valve opening rises from 0 to

1, the measure of flow capacity scales from its specified

minimum to its specified maximum.

Momentum Balance

The block equations depend on the Valve parameterization parameter.

When you set Valve parameterization to Cv flow

coefficient, the mass flow rate, , is

where:

Cv is the value of the Maximum Cv flow coefficient parameter.

Sopen is the valve opening area.

SMax is the maximum valve area when the valve is fully open.

N6 is a constant equal to 27.3 for mass flow rate in kg/hr, pressure in bar, and density in kg/m3.

Y is the expansion factor.

pin is the inlet pressure.

pout is the outlet pressure.

ρin is the inlet density.

The expansion factor is

where:

Fγ is the ratio of the isentropic exponent to 1.4.

xT is the value of the xT pressure differential ratio factor at choked flow parameter.

The block smoothly transitions to a linearized form of the equation when the pressure ratio, , rises above the value of the Laminar flow pressure ratio parameter, Blam,

where:

When the pressure ratio, , falls below , the orifice becomes choked and the block switches to the equation

When you set Valve parameterization to Kv flow

coefficient, the block uses these same equations, but replaces

Cv with

Kv by using the relation . For more information on the mass flow equations when the

Valve parameterization parameter is Kv

flow coefficient or Cv flow

coefficient, [2][3].

When you set Valve parameterization to Sonic

conductance, the mass flow rate, , is

where:

C is the value of the Maximum sonic conductance parameter.

Bcrit is the critical pressure ratio.

m is the value of the Subsonic index parameter.

Tref is the value of the ISO reference temperature parameter.

ρref is the value of the ISO reference density parameter.

Tin is the inlet temperature.

The block smoothly transitions to a linearized form of the equation when the pressure ratio, , rises above the value of the Laminar flow pressure ratio parameter Blam,

When the pressure ratio, , falls below the critical pressure ratio, Bcrit, the orifice becomes choked and the block switches to the equation

The Sonic conductance setting of the

Valve parameterization parameter is for pneumatic

applications. If you use this setting for moist air with high levels of trace

gasses or are modeling a fluid other than air, you may need to scale the sonic

conductance by the square root of the mixture specific gravity.

For more information on the mass flow equations when the Valve

parameterization parameter is Sonic

conductance, see [1].

When you set Valve parameterization to Orifice area

based on geometry, the mass flow rate, , is

where:

Sopen is the valve opening area.

S is the value of the Cross-sectional area at ports A and B parameter.

Cd is the value of the Discharge coefficient parameter.

γ is the isentropic exponent.

The block smoothly transitions to a linearized form of the equation when the pressure ratio, , rises above the value of the Laminar flow pressure ratio parameter, Blam,

When the pressure ratio, , falls below , the orifice becomes choked and the block switches to the equation

For more information on the mass flow equations when the Valve

parameterization parameter is Orifice area based on

geometry, see [4].

Mass Balance

The block conserves mass through the valve

where ṁ is the mass flow rate and the subscript w denotes water vapor, the subscript g denotes trace gas, and the subscript d denotes water droplets.

Energy Balance

The resistive element of the block is an adiabatic component. No heat exchange can occur between the fluid and the wall that surrounds it. No work is done on or by the fluid as it traverses from inlet to outlet. Energy can flow only by advection, through ports A and B. By the principle of conservation of energy, the sum of the port energy flows is always equal to zero

where ϕ is the energy flow rate into the valve through ports A or B.

Assumptions and Limitations

This block does not model supersonic flow.

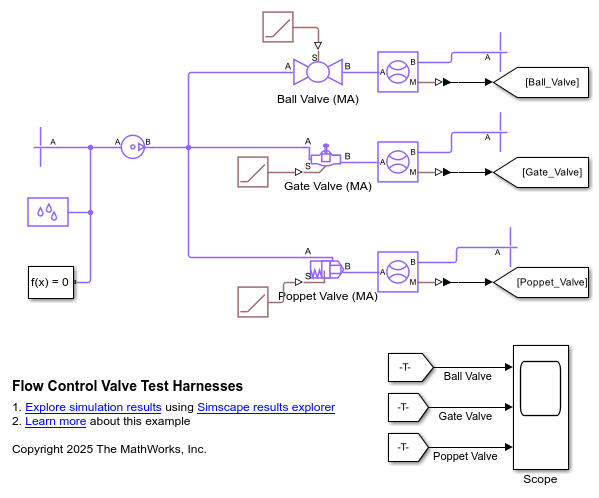

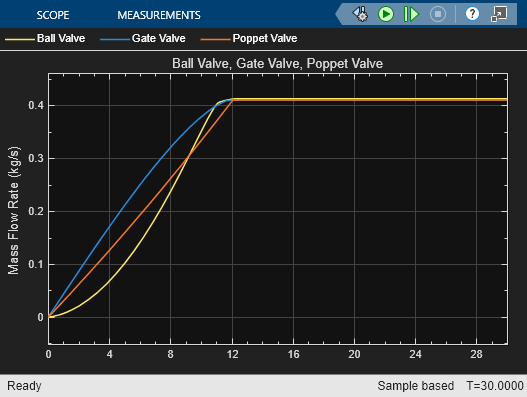

Examples

Ports

Conserving

Input

Parameters

Extended Capabilities

Version History

Introduced in R2025a