spsConversionAssistant

Convert Specialized Power Systems model into Simscape Electrical model

Since R2025b

Syntax

Description

Note

For more information about upgrading Specialized Power Systems models, see Upgrade Specialized Power Systems Models to use Simscape Electrical Blocks.

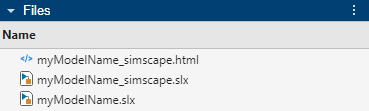

spsConversionAssistant tries to replace the Specialized Power

Systems library blocks in the currently open model with Simscape™

Electrical™ library blocks, while preserving the parameter values and connections between

blocks. The function saves the converted model in the same folder as the original model and

generates an HTML report that lists the fully supported, partially supported, and

unsupported blocks. The file name of the converted model is the original model name with

_simscape appended to the end.

After the conversion finishes, review the replaced blocks and manually convert the unsupported blocks to Simscape and Simscape Electrical blocks.

spsConversionAssistant( converts the

blocks in the model, modelName)modelName. The model must be loaded or on your

MATLAB® search path. Alternatively, specify the modelName

argument as a character vector or string scalar that contains an absolute or relative path

name.

spsConversionAssistant(

saves the converted model in the specified folder, modelName,outputFolder)outputFolder. The

function creates the folder if it does not exist.

writable = spsConversionAssistant(___)1 if the file and folder permissions allow the function to save

the converted model. Otherwise, this function returns 0.

Examples

Input Arguments

Output Arguments

Tips

To minimize differences between the simulation results of the original and converted models, try resolving the simulation warnings in your original model before the conversion. For more information about simulation errors and warnings, see Systematic Diagnosis of Errors and Warnings.

You can also try to minimize differences between the simulation results of the original and converted models by tightening the solver tolerances. To specify the solver tolerances, open the Configuration Parameters dialog box. In the Simulink® Editor, on the Modeling tab, click Model Settings. In the Configuration Parameters dialog box, click the Solver pane and expand the Solver Details section. Set the Relative tolerance and Absolute tolerance parameter values to

1e-3or1e-4. Do not set these parameters toauto. For more information, see Solver Pane.If your original model contains controllers with direct feedthrough, the converted model might exhibit algebraic loops. Consider measurement filtering, including using low-pass filters or introducing sensor latency, and actuation delays to try to avoid algebraic loops in the simulation.

In Simscape, you are not required to specify an on-state inductance parameter for switches. You might be able to eliminate snubber circuits from your original model, as Simscape handles ideal switching events without additional snubber components to aid numerical convergence.

When you simulate the converted model, the initialization values at time 0 might be different than in your original model. To improve initialization behavior and get the initialization values at time 0 closer to the initialization values of the original model, review the initial target values in your blocks and specify appropriate steady-state values. For more information about initial targets, see Set Priority and Initial Target for Block Variables.

During the simulation, timing jitter might occur in switching events, especially in models that use pulse-width modulation (PWM) signals in closed-loop control systems. As a result, instantaneous signal values might differ between models. When you evaluate the conversion results, focus on the peak and averaged signal values instead. Minor discrepancies due to timing jitter are expected and do not typically impact the overall model behavior. However, if you observe significant differences in peak or averaged values, review the model for initialization differences and partially supported or unsupported conversions.

Select

ode23tordaesscas the solver for your converted model. For more information about solvers in physical models, see Making Optimal Solver Choices for Physical Simulation.If your original model uses a continuous solver, the converted model might generate different results due to the solver configuration. To help remove issues with the solver configurations and obtain comparable results:

Set the Simulation type parameter of the powergui block in your original model to

Discrete.In the Solver Configuration block of your converted model, select the Use local solver parameter.

Specify the same value for both the Sample time (s) parameter in the powergui block of the original model and the Sample time parameter in the Solver Configuration block of the converted model.

Version History

Introduced in R2025b