Parameter Configuration

You can direct Simulink Design Verifier to consider additional values for model parameters during its analysis other than their defaults set in the base workspace or a data dictionary. This allows Simulink Design Verifier can handle parameters in your model as variables throughout the analysis process. A parameter configuration defines the range of permissible values for a parameter.

For example, consider a model that contains a Switch

block with the default value set to 0, and its

control port influenced by a calibration parameter value

K. Different values of K

influence whether the control port condition is reported as dead or

active logic and impact test case parameter values. For more

information, see Use Parameter Configuration in Analysis.

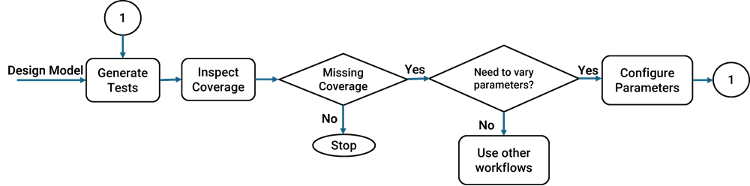

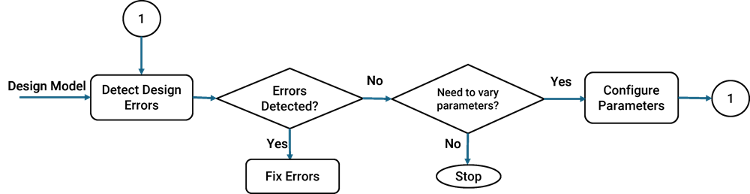

When you configure parameters depends on which workflow you use.

Configure parameters when you generate test cases for coverage - In this workflow, you vary the parameters after assessing whether the parameter values impact model coverage objectives.

Configure parameters during design error detection analysis - In this workflow you vary parameters after detecting design errors to check if any parameter values result in a run-time error in the logic that uses these values.

Topics

Basics of Parameter Configuration

- Use Parameter Configuration in Analysis

Overview of parameter configuration for Simulink Design Verifier analysis. - Create Parameter Configuration for Simulink Design Verifier Analysis

Configure parameters in a model for analysis. - Parameter Configuration for Variant Blocks

Use parameters to select variants in model. - Import and Export Parameter Constraints

An example on how to import and export specified parameter constraints to and from the Parameter Table.

Example Workflows

- Automatically Infer Parameter Specification for Analysis

Describes about a workflow to specify parameter configuration. - Determine Parameters from Generated Code

Describes about a workflow to specify parameter configuration. - Use Parameter Table to Find Constraints

An example of how to specify parameters as variables for analysis. - Set Parameters Using Parameter Configuration File

Describes how to define parameter configurations in MATLAB® code files. - Specify Parameter Configuration for Structure or Bus Parameters

This example describes how to generate tests that constrain the values for the structures and bus signals in a model. - Specify Parameter Configuration for Full Coverage

An example of how to specify parameter constraint values to achieve full model coverage.