Compute Operating Points from Specifications at the Command Line

You can compute a steady-state operating point of a Simulink® model by specifying constraints on the model states, outputs, and inputs, and by finding a model operating condition that satisfies these constraints. For more information on steady-state operating points, see About Operating Points and Compute Steady-State Operating Points.

To find an operating point for your Simulink model, you can programmatically trim your model using the findop, as shown in this example.

Alternatively, you can trim your model in the:

Steady State Manager. For more information, see Compute Operating Points from Specifications Using Steady State Manager.

Model Linearizer. For more information, see Compute Operating Points from Specifications Using Model Linearizer.

In this example, you compute an operating point to meet output specifications. Using a similar approach, you can define state or input specifications. Also, you can define a combination of state, output, and input specifications; that is, you do not have to use, for example, only state specifications.

For more information on trimming your model to meet specifications, see Compute Steady-State Operating Points from Specifications.

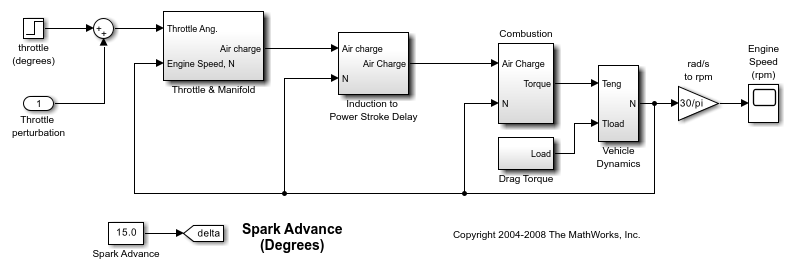

Open Simulink Model

Open the Simulink model.

mdl = 'scdspeed';

open_system(mdl)

Define Operating Point Specifications

Create a default operating point specification for the model.

opspec = operspec(mdl)

opspec =

Operating point specification for the Model scdspeed.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) scdspeed/Throttle & Manifold/Intake Manifold/p0 = 0.543 bar

0.543 false true -Inf Inf -Inf Inf

(2.) scdspeed/Vehicle Dynamics/w = T//J w0 = 209 rad//s

209.48 false true -Inf Inf -Inf Inf

Inputs:

----------

u Known Min Max

_____ _____ _____ _____

(1.) scdspeed/Throttle perturbation

0 false -Inf Inf

Outputs: None

----------

Since there are no root-level outputs in the model, the default operating point specification object has no output specifications.

For this example, specify a known steady-state engine speed. To do so, add an output specification at the output of the rad/s to rpm block.

opspec = addoutputspec(opspec,'scdspeed/rad//s to rpm',1);

Specify a known value of 2000 rpm for the output constraint.

opspec.Outputs(1).Known = 1; opspec.Outputs(1).y = 2000;

View the updated operating point specification.

opspec

opspec =

Operating point specification for the Model scdspeed.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) scdspeed/Throttle & Manifold/Intake Manifold/p0 = 0.543 bar

0.543 false true -Inf Inf -Inf Inf

(2.) scdspeed/Vehicle Dynamics/w = T//J w0 = 209 rad//s

209.48 false true -Inf Inf -Inf Inf

Inputs:

----------

u Known Min Max

_____ _____ _____ _____

(1.) scdspeed/Throttle perturbation

0 false -Inf Inf

Outputs:

----------

y Known Min Max

_____ _____ _____ _____

(1.) scdspeed/rad//s to rpm

2000 true -Inf Inf

Trim Model

Find an operating point that meets these specifications.

op1 = findop(mdl,opspec);

Operating point search report:

---------------------------------

opreport =

Operating point search report for the Model scdspeed.

(Time-Varying Components Evaluated at time t=0)

Operating point specifications were successfully met.

States:

----------

Min x Max dxMin dx dxMax

___________ ___________ ___________ ___________ ___________ ___________

(1.) scdspeed/Throttle & Manifold/Intake Manifold/p0 = 0.543 bar

-Inf 0.54363 Inf 0 2.6649e-13 0

(2.) scdspeed/Vehicle Dynamics/w = T//J w0 = 209 rad//s

-Inf 209.4395 Inf 0 -8.4758e-12 0

Inputs:

----------

Min u Max

_________ _________ _________

(1.) scdspeed/Throttle perturbation

-Inf 0.0038183 Inf

Outputs:

----------

Min y Max

____ ____ ____

(1.) scdspeed/rad//s to rpm

2000 2000 2000

The operating point search report shows that the specifications were met successfully, and that both states are at steady state as expected (dx = 0).

You can also specify bounds for outputs during trimming. For example, suppose that you know that there is a steady-state condition between 1900 and 2100 rpm. To trim the speed to this range, modify the operating point specifications.

opspec.Outputs(1).Min = 1900; opspec.Outputs(1).Max = 2100;

In this case, since you do not know the output value, specify the output as unknown. You can also provide an initial guess for the output value.

opspec.Outputs(1).Known = 0; opspec.Outputs(1).y = 2050;

Find an operating point that meets these specifications.

op2 = findop(mdl,opspec);

Operating point search report:

---------------------------------

opreport =

Operating point search report for the Model scdspeed.

(Time-Varying Components Evaluated at time t=0)

Operating point specifications were successfully met.

States:

----------

Min x Max dxMin dx dxMax

___________ ___________ ___________ ___________ ___________ ___________

(1.) scdspeed/Throttle & Manifold/Intake Manifold/p0 = 0.543 bar

-Inf 0.5436 Inf 0 2.9879e-13 0

(2.) scdspeed/Vehicle Dynamics/w = T//J w0 = 209 rad//s

-Inf 209.4799 Inf 0 -9.8968e-13 0

Inputs:

----------

Min u Max

_________ _________ _________

(1.) scdspeed/Throttle perturbation

-Inf 0.0050021 Inf

Outputs:

----------

Min y Max

_________ _________ _________

(1.) scdspeed/rad//s to rpm

1900 2000.3853 2100

The operating point search report shows that the specifications were met successfully.

After trimming your model, you can:

Linearize your model at the resulting operating point. For more information, see Linearize at Trimmed Operating Point.

Simulate your model at the resulting operating point. For more information, see Simulate Simulink Model at Specific Operating Point.

See Also

findop | addoutputspec | operspec