Rod

Axially flexible bar or cable

Libraries:

Simscape /

Driveline /

Couplings & Drives

Description

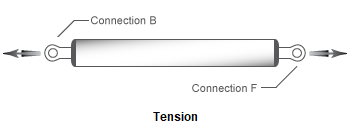

The Rod block represents an axially flexible bar or cable in tension or compression.

Model

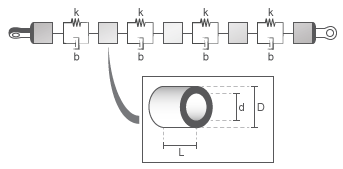

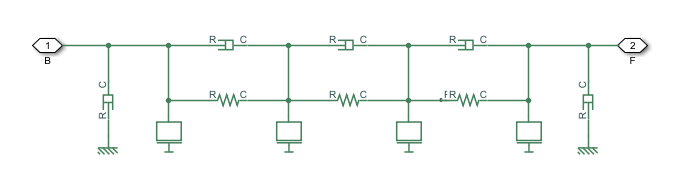

To represent the bar or cable, the block uses a lumped parameter model. The model is composed of N+1 lumped masses that are connected in series by N sets of parallel-connected spring and damper circuits. The spring represents elasticity. The damper represents material damping.

A single flexible element model exhibits an eigenfrequency that is close to the first eigenfrequency of the distributed parameter model. For more accurate analysis, select 2, 4, 8, or more flexible elements.

The equivalent physical network contains N spring and damper circuits and N+1 mass blocks. The total mass of the rod is distributed evenly over the mass blocks. The stiffness of the spring in each spring and damper circuit is equal to the N times the stiffness of the rod material.

Equations

The defining equations for the model are:

Where:

η is the damping of the rod.

ς is the damping ratio of the rod material.

K is the stiffness of the rod.

A is the cross-sectional area of the rod.

D is the outer diameter of the rod.

d is the inner diameter of the rod, where

d = 0 for a solid rod.

d > 0 for an annular, that is, hollow, rod.

E is Young's modulus, that is, the modulus of elasticity, of the rod material.

L is the length of the rod.

m is the mass of the rod.

ρ is the density of the rod material.

Assumptions and Limitations

The rod does not buckle, in the case of a bar, or go slack, in the case of a cable, in tension.

The rod has a constant cross-section along its length.

The distributed parameter model is approximated as a finite number of flexible elements, N.

Ports

Conserving

Parameters

Extended Capabilities

Version History

Introduced in R2018b

See Also

Flexible Shaft | Mass | Translational Damper | Translational Spring