Virtual Commissioning of Production Machines

Modern production machines contain an increasingly complex amount of real-time software, typically running on a PLC, PAC, or industrial PC. In order to test and verify the functionality before the physical machine is available, virtual commissioning based on modeling, simulation, and code generation has become a well-proven design workflow. MathWorks software for physical modeling, including CAD import, is used to implement the plant model. Simulink® and Stateflow® help engineers to design, parameterize, and test their closed-loop control software and state machines. Finally, automatic code generation of real-time C/C++ or IEC 61131-3 ST/LD code is used to implement the previously tested functionality on a PLC.

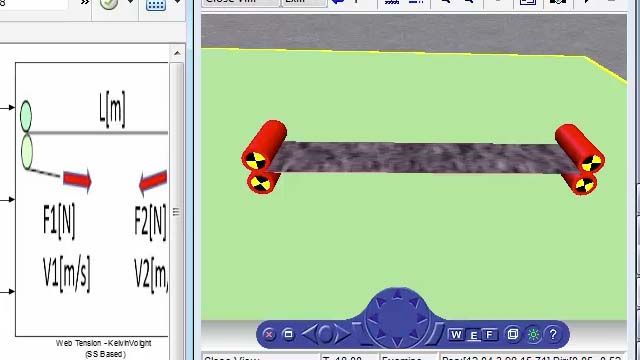

Perform virtual commissioning of a web tension controller using Model-Based Design with Simulink.

Model the dynamics of the web system using first principles in Simulink and physical modeling in Simscape.

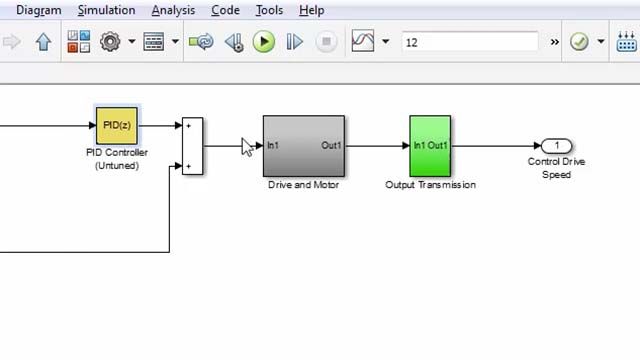

Tune the PID controller gains for the control drive using Simulink Control Design and verify results by running closed-loop simulation in Simulink.

Design supervisory control logic using Stateflow.

Automatically generate IEC 61131 structured text from a Simulink model using Simulink PLC Coder for implementing the controller on a PLC.

Review recap on how Model-Based Design with Simulink is used for virtual commissioning of a web tension controller.