Reducing Unplanned Repair Costs Using Predictive Maintenance with MATLAB

Maureen Barker, Urenco

Urenco provides safe, cost effective and reliable uranium enrichment services and fuel cycle products for power generation within a framework of high environmental, social responsibility and corporate governance standards.

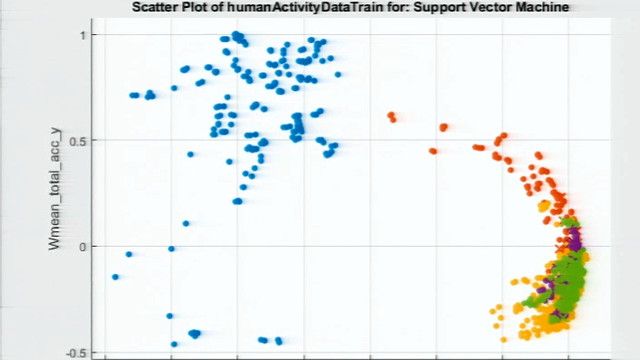

Ensuring the safe medium-term storage of legacy waste in a controlled environment presents several unique challenges. These include reducing exposure to hazardous working environments and minimising costs associated with unplanned manual inspection and repairs. Predicting the expected failure time, or equivalently the remaining useful life (RUL) of a storage container requires a data-driven modelling and simulation approach, fully utilising inspection data which is often time consuming and costly to gather.

Discover how Urenco applies statistical modelling, Monte Carlo simulation and predictive maintenance algorithms to model the RUL of containers in a secure storage facility.

Published: 4 Nov 2024