Discrete-Valued Variables in Response Optimization (Code)

This example shows how to use response optimization to tune discrete-valued variables. Discrete-valued variables represent model parameters that are restricted to a finite set of values, instead of continuously varying. To use discrete-valued variables for response optimization or parameter estimation, you must use the surrogateopt solver for mixed-integer optimization.

Open the Model

In the sdoMotorPosition model, a PI controller enables the angular position of a DC motor to match a desired reference value. The load on the motor is subject to disturbances, and the controller must reject these disturbances.

open_system('sdoMotorPosition')

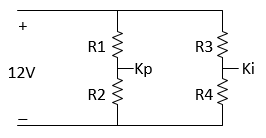

Within the Controller subsystem, the PI gains are set by a 12 V source divided down by resistors R1, R2, R3, and R4, as shown in the following diagram.

The proportional gain, Kp, is given by 12*R2/(R1+R2) and the integral gain, Ki, is given by 12*R4/(R3+R4). The initial values of the resistances are R1 = 47 kΩ, R2 = 180 kΩ, R3 = 10 kΩ, and R4 = 10 kΩ.

Specify Discrete Design Variables

Those four resistor values are the model parameters to tune for the optimization. Because resistors are only available in discrete values, use discrete parameters to represent them. To do so, use third input argument to sdo.getParameterFromModel to specify discrete parameters.

DesignVars = sdo.getParameterFromModel('sdoMotorPosition',[],{'R1','R2','R3','R4'});

sdo.getParameterFromModel returns an array of param.Discrete parameter objects that correspond to the model parameters in the order you specified. Set the ValueSet property of each parameter to the set of discrete values allowed for the parameter. Set the Value property to the current value, which must be present in ValueSet.

% R1 values DesignVars(1).ValueSet = [39 43 47 51 56] * 1e3; DesignVars(1).Value = 47*1e3; % R2 values DesignVars(2).ValueSet = [150 160 180 200 220] * 1e3; DesignVars(2).Value = 180*1e3; % R3 values DesignVars(3).ValueSet = [8.2 9.1 10 11 12] * 1e3; DesignVars(3).Value = 10*1e3; % R4 values DesignVars(4).ValueSet = [8.2 9.1 10 11 12] * 1e3; DesignVars(4).Value = 10*1e3;

Specify Design Requirements and Signals

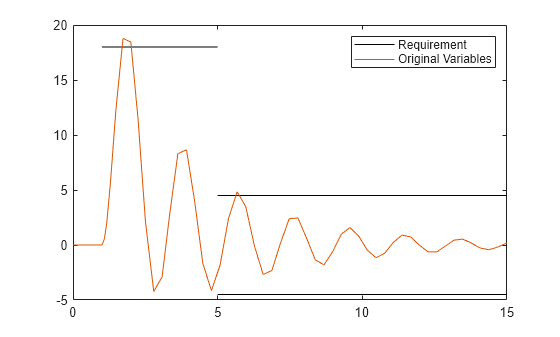

The model applies a step disturbance at 1 second. With the initial resistance values specified in the model, the disturbance causes the motor to deviate by about 20°. The response then settles back to within ±5° of the reference position by 4 seconds after the disturbance. For this example, find new resistor values to improve this specification by 10%, so that the motor deviates no more than 18°, and settles back to within ±4.5° degrees of the reference position by 4 seconds after the disturbance. First, specify these new design requirements using sdo.requirements.SignalBound.

Requirements = struct; Requirements.UpperBound = sdo.requirements.SignalBound(... 'BoundMagnitudes', [18 18 ; 4.5 4.5], ... 'BoundTimes', [1 5 ; 5 15]); Requirements.LowerBound = sdo.requirements.SignalBound(... 'BoundMagnitudes', [-4.5 -4.5], ... 'BoundTimes', [5 15], ... 'Type', '>=');

To visualize the initial performance against the requirement, first specify signals to log during simulation. In particular, log the output of the Integrator block, which is the angular position of the model, the signal you want to optimize. To do so, create a simulation scenario with sdo.SimulationTest and configure its LoggingInfo property. Also, to prepare the scenario for later use in the optimization, assign the design variables you created as its Parameters property.

Simulator = sdo.SimulationTest('sdoMotorPosition'); Sig_Info = Simulink.SimulationData.SignalLoggingInfo; Sig_Info.BlockPath = 'sdoMotorPosition/Integrator'; Sig_Info.LoggingInfo.LoggingName = 'Sig'; Sig_Info.LoggingInfo.NameMode = 1; Simulator.LoggingInfo.Signals = Sig_Info; Simulator.Parameters = DesignVars;

Now create a plot of the disturbance-rejection requirements. Then, simulate the model and add the logged signal to the plot.

hRequirement = plot( ... Requirements.LowerBound.BoundTimes', ... Requirements.LowerBound.BoundMagnitudes', ... 'color','black'); hold on plot( ... Requirements.UpperBound.BoundTimes', ... Requirements.UpperBound.BoundMagnitudes', ... 'color','black'); % Simulator.Parameters = DesignVars; Simulator = sim(Simulator); SimLog = find(Simulator.LoggedData, ... get_param('sdoMotorPosition','SignalLoggingName')); Sig_Log = find(SimLog,'Sig'); clrs = colororder; hOriginal = plot(Sig_Log.Values,'Color',clrs(2,:)); legend([hRequirement hOriginal],'Requirement','Original Variables');

The plot shows that the current resistor values do not quite satisfy the more stringent requirement.

Set Up Optimization

The optimization process runs the model many times with different values for the resistor variables. To expedite this, configure the simulator for fast restart.

Simulator = setup(Simulator,FastRestart='on');Optimization requires an objective or cost function that runs the model and determines whether the disturbance rejection requirements are satisfied. For this example, use the function sdoMotorPosition_optFcn, which is included at the end of the example. This function is called many times by the optimization solver. To pass the function to the optimizer, use an anonymous function with one argument that calls sdoMotorPosition_optFcn.

optimfcn = @(P) sdoMotorPosition_optFcn(P,Simulator,Requirements);

Specify optimization options. Set the optimization method to surrogateopt solver, which is the method that supports tuning of discrete parameters.

Options = sdo.OptimizeOptions;

Options.Method = 'surrogateopt';

Options.MethodOptions.MaxFunctionEvaluations = 100;

Options.MethodOptions.ObjectiveLimit = 0.001;

Options.OptimizedModel = Simulator;Optimize the Design

To find resistance values optimized for the requirements, call sdo.optimize with the cost function handle, parameters to optimize, and options.

rng('default'); % for reproducibility [Optimized_DesignVars,Info] = sdo.optimize(optimfcn,DesignVars,Options);

Optimization started 2025-Aug-12, 18:41:23

Current

F-count max constraint max constraint Trial type

1 0.0759805 0.0759805 initial

2 0.0751287 0.0751287 random

3 0.0751287 0.179179 random

4 0.0447169 0.0447169 random

5 0.0317818 0.0317818 random

6 0.0317818 0.261353 random

7 0.0257711 0.0257711 random

8 0.0257711 0.0930365 random

9 0.0257711 0.0971938 random

10 0.0257711 0.200359 random

11 0.0062997 0.0062997 random

12 0.0062997 0.206374 random

13 0.0062997 0.0818387 random

14 0.0062997 0.0585416 random

15 0.0062997 0.114002 random

16 0.0062997 0.112485 random

17 0.0062997 0.0759805 random

18 0.0062997 0.0709489 random

19 0.0062997 0.280136 random

20 0.0062997 0.099985 random

21 -0.00759693 -0.00759693 adaptive

22 -0.00759693 0.0691728 random

23 -0.00759693 0.0347164 random

24 -0.00759693 0.0977682 random

25 -0.00759693 0.0589627 random

26 -0.00759693 0.131778 random

27 -0.00759693 0.147347 random

28 -0.00759693 0.104488 random

29 -0.00759693 0.0534262 random

30 -0.00759693 0.1643 random

31 -0.00759693 0.0419731 random

32 -0.00759693 0.0396579 random

33 -0.00759693 0.077945 random

34 -0.00759693 0.0883493 random

35 -0.00762259 -0.00762259 random

36 -0.00762259 0.0455853 random

37 -0.00762259 0.13976 random

38 -0.00762259 0.140634 random

39 -0.00762259 0.0662368 random

40 -0.00762259 0.256738 random

41 -0.00762259 0.0348764 random

42 -0.00762259 0.18995 random

43 -0.00762259 0.0615952 random

44 -0.00762259 0.0597358 random

45 -0.00762259 0.015983 random

46 -0.00762259 0.0770592 random

47 -0.00762259 0.174666 random

48 -0.00762259 0.081758 random

49 -0.00762259 0.0240828 random

50 -0.00762259 0.173292 random

Current

F-count max constraint max constraint Trial type

51 -0.00762259 0.116519 random

52 -0.00762259 0.217099 random

53 -0.00762259 0.104371 random

54 -0.00762259 0.0937562 random

55 -0.00762259 0.104225 random

56 -0.00762259 0.0380129 random

57 -0.00762259 0.150819 random

58 -0.00762259 0.0636666 random

59 -0.00762259 0.0320499 random

60 -0.00762259 0.0273158 random

61 -0.00762259 0.0798937 random

62 -0.00762259 0.174146 random

63 -0.00762259 0.0166127 random

64 -0.00762259 0.00433873 adaptive

65 -0.00762259 0.294106 random

66 -0.00518218 -0.00518218 adaptive

67 -0.00518218 0.0319864 random

68 -0.00518218 0.266843 random

69 -0.00518218 0.0342618 random

70 -0.00518218 0.0982987 random

71 -0.00518218 0.0419731 random

72 -0.00518218 0.0396579 random

73 -0.00518218 0.299815 random

74 -0.00518218 0.0712971 random

75 -0.00518218 0.0709489 random

76 -0.00518218 0.0589627 random

77 -0.00518218 0.131778 random

78 -0.00518218 0.00653156 random

79 -0.00518218 0.211877 random

80 -0.00518218 0.0967155 random

81 -0.00518218 0.0689487 random

82 -0.00518218 0.0257711 random

83 -0.00518218 0.0930365 random

84 -0.00518218 0.114002 random

85 -0.00518218 0.112485 random

86 -0.00518218 0.06706 random

87 -0.00518218 0.0751287 random

88 -0.00737024 -0.00737024 adaptive

89 -0.00737024 0.0759805 random

90 -0.00737024 0.10447 random

91 -0.00737024 0.190644 random

92 -0.00737024 0.142755 random

93 -0.00737024 0.104193 random

94 -0.00737024 0.100237 random

95 -0.00737024 0.097787 random

96 -0.00737024 0.0735855 random

97 -0.00737024 0.137557 random

98 -0.00737024 0.0783709 random

99 -0.00737024 0.0875674 random

100 -0.00737024 0.0794652 random

101 -0.00737024 -0.00737024 best value

The current solution is feasible. surrogateopt stopped because it exceeded the function evaluation limit set by the 'MethodOptions.MaxFunctionEvaluations' property in the sdo.OptimizeOptions object.

If the solution needs to be improved, you could try increasing the function evaluation limit.

Evaluate Optimized Design

Plot the model response after optimization.

Simulator.Parameters = Optimized_DesignVars; Simulator = sim(Simulator); SimLog = find(Simulator.LoggedData, ... get_param('sdoMotorPosition','SignalLoggingName')); Sig_Log = find(SimLog,'Sig'); clrs = colororder; hOptimized = plot(Sig_Log.Values, 'Color', clrs(1,:)); legend([hRequirement hOriginal hOptimized], ... 'Requirement','Original Variables','Optimized Variables');

Now the motor position is within the spec of the disturbance rejection requirement.

Update Model with Optimized Parameter Values

sdo.Optimize returns tuned versions of the parameters in the array Optimized_DesignVars. Each entry in this array is a param.Discrete parameter object whose Value property is set to the optimized value. For instance, examine the new value of R2.

Optimized_DesignVars(2).Value

ans = 220000

Update the model with the optimized parameter values.

sdo.setValueInModel('sdoMotorPosition',Optimized_DesignVars);Restore the simulator fast restart settings.

Simulator = restore(Simulator);

Conclusion

In this example you tuned variables to improve the disturbance rejection characteristics of a motor controller. The variables being tuned were electrical component parts that could only take on discrete values, rather than continuous values. You used sdo.getParameterFromModel to specify the variables as discrete, and used the surrogateopt solver to tune the parameters.

Objective Function

The function sdoMotorPosition_optFcn is called at each iteration of the optimization problem with a set of parameter values, P. The function returns the objective value and constraint violations, Vals, to the optimization solver. See sdo.optimize for a more detailed description of the function signature.

function Vals = sdoMotorPosition_optFcn(P,Simulator,Requirements) %SDOMOTORPOSITION_OPTFCN % % Simulate the model. Simulator.Parameters = P; Simulator = sim(Simulator); % Retrieve logged signal data. SimLog = find(Simulator.LoggedData, ... get_param('sdoMotorPosition','SignalLoggingName')); Sig_Log = find(SimLog,'Sig'); % Evaluate the design requirements. Cleq_UpperBound = evalRequirement( ... Requirements.UpperBound,Sig_Log.Values); Cleq_LowerBound = evalRequirement( ... Requirements.LowerBound,Sig_Log.Values); % Collect the evaluated design requirement values in a structure to % return to the optimization solver. Vals.Cleq = [... Cleq_UpperBound(:); ... Cleq_LowerBound(:)]; end

See Also

sdo.optimize | param.Discrete | sdo.getParameterFromModel | sdo.OptimizeOptions