Variable Step Solvers in Simulink

Variable-step solvers vary the step size during the simulation, reducing the step size to increase accuracy when model states are changing rapidly and increasing the step size to avoid taking unnecessary steps when model states are changing slowly. Computing the step size adds to the computational overhead at each step but can reduce the total number of steps, and hence simulation time, required to maintain a specified level of accuracy for models with rapidly changing or piecewise continuous states.

When you set the Type control of the Solver configuration pane to Variable-step,

the Solver control allows you to choose one of the

variable-step solvers. As with fixed-step solvers, the set of variable-step solvers

comprises a discrete solver and a collection of continuous solvers. However, unlike the

fixed-step solvers, the step size varies dynamically based on the local error.

The choice between the two types of variable-step solvers depends on whether the blocks in your model define states and, if so, the type of states that they define. If your model defines no states or defines only discrete states, select the discrete solver. If the model has continuous states, the continuous solvers use numerical integration to compute the values of the continuous states at the next time step.

Note

If a model has no states or only discrete states, Simulink® uses the discrete solver to simulate the model even if you specify a continuous solver.

Variable-Step Discrete Solver

Use the variable-step discrete solver when your model does not contain continuous states. For such models, the variable-step discrete solver reduces its step size in order to capture model events such as zero-crossings, and increases the step size when it is possible to improve simulation performance.

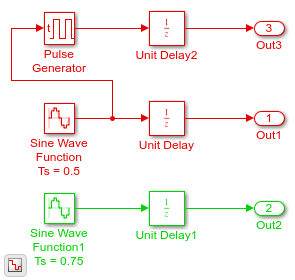

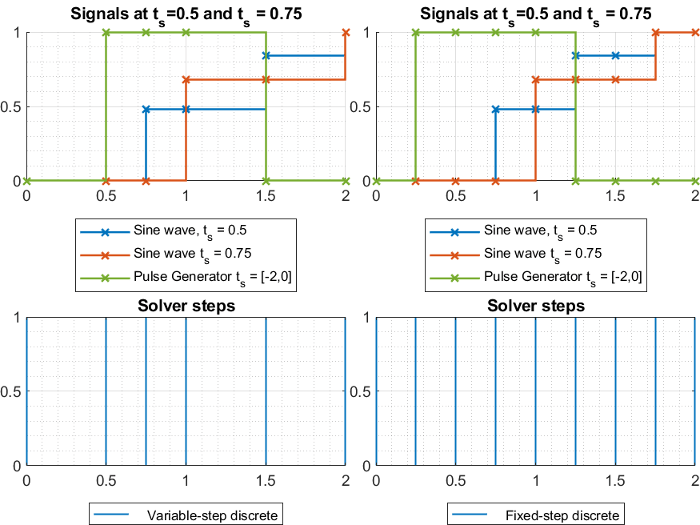

The model shown in the figure contains two discrete sine wave signals at 0.5 and 0.75 sample times. The graphs below show the signals in the model along with the solver steps for the variable-step discrete and the fixed-step discrete solvers respectively. You can see that the variable-step solver only takes the steps needed to record the output signal from each block. On the other hand, the fixed-step solver will need to simulate with a fixed-step size, or fundamental sample time, of 0.25 to record all the signals, thus taking more steps overall.

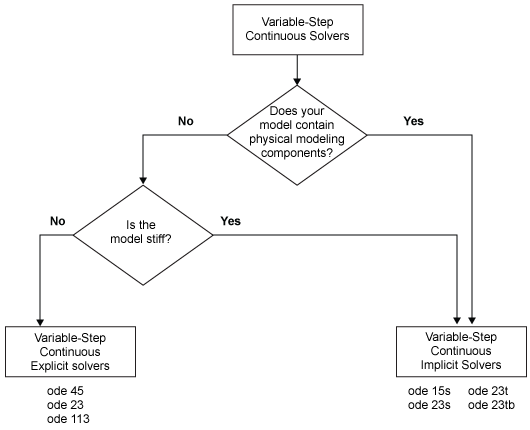

Variable-Step Continuous Solvers

Variable-step solvers dynamically vary the step size during the simulation. Each of these solvers increases or reduces the step size using its local error control to achieve the tolerances that you specify. Computing the step size at each time step adds to the computational overhead. However, it can reduce the total number of steps, and the simulation time required to maintain a specified level of accuracy.

You can further categorize the variable-step continuous solvers as one-step or multistep, single-order or variable-order, and explicit or implicit. See One-Step Versus Multistep Continuous Solvers for more information.

Variable-Step Continuous Explicit Solvers

The variable-step explicit solvers are designed for nonstiff problems. Simulink provides four such solvers:

ode45ode23ode113odeN

| ODE Solver | One-Step Method | Multistep Method | Order of Accuracy | Method |

|---|---|---|---|---|

ode45 | X | Medium | Runge-Kutta, Dormand-Prince (4,5) pair | |

ode23 | X | Low | Runge-Kutta (2,3) pair of Bogacki & Shampine | |

ode113 | X | Variable, Low to High | PECE Implementation of Adams-Bashforth-Moulton | |

odeN | X | See Order of Accuracy in Fixed-Step Continuous Explicit Solvers | See Integration Technique in Fixed-Step Continuous Explicit Solvers |

Note

Select the odeN solver when simulation speed is important,

for example, when

The model contains lots of zero-crossings and/or solver resets

The Solver Profiler does not detect any failed steps when profiling the model

Variable-Step Continuous Implicit Solvers

If your problem is stiff, try using one of the variable-step implicit solvers:

ode15sode23sode23tode23tb

| ODE Solver | One-Step Method | Multistep Method | Order of Accuracy | Solver Reset Method | Max. Order | Method |

|---|---|---|---|---|---|---|

ode15s | X | Variable, low to medium | X | X | Numerical Differentiation Formulas (NDFs) | |

ode23s | X | Low | Second-order, modified Rosenbrock formula | |||

ode23t | X | Low | X | Trapezoidal rule using interpolant | ||

ode23tb | X | Low | X | TR-BDF2 |

Solver Reset Method

For ode15s, ode23t, and

ode23tb a drop-down menu for the Solver reset

method appears in the Solver details

section of the Configuration pane. This parameter controls how the solver treats a

reset caused, for example, by a zero-crossing detection. The options allowed are

Fast and Robust.

Fast specifies that the solver does not recompute the

Jacobian for a solver reset, whereas Robust specifies

that the solver does. Consequently, the Fast setting is

computationally faster but it may use a small step size in certain cases. To test

for such cases, run the simulation with each setting and compare the results. If

there is no difference in the results, you can safely use the

Fast setting and save time. If the results differ

significantly, try reducing the step size for the fast simulation.

Maximum Order

For the ode15s solver, you can choose the maximum order of the

numerical differentiation formulas (NDFs) that the solver applies. Since the

ode15s uses first- through fifth-order formulas, the

Maximum order parameter allows you to choose orders 1 through

5. For a stiff problem, you may want to start with order 2.

Tips for Choosing a Variable-Step Implicit Solver

The following table provides tips for the application of variable-step implicit solvers. For an example comparing the behavior of these solvers, see Explore Variable-Step Solvers with Stiff Model.

Note

For a stiff problem, solutions can change on a time scale that is very small as compared to the interval of integration, while the solution of interest changes on a much longer time scale. Methods that are not designed for stiff problems are ineffective on intervals where the solution changes slowly because these methods use time steps small enough to resolve the fastest possible change. For more information, see Shampine, L. F., Numerical Solution of Ordinary Differential Equations, Chapman & Hall, 1994.

Error Tolerances for Variable-Step Solvers

Local Error

The variable-step solvers use standard control techniques to monitor the local error at each time step. During each time step, the solvers compute the state values at the end of the step and determine the local error—the estimated error of these state values. They then compare the local error to the acceptable error, which is a function of both the relative tolerance (rtol) and the absolute tolerance (atol). If the local error is greater than the acceptable error for any one state, the solver reduces the step size and tries again.

Relative tolerance measures the error relative to the size of each state. The relative tolerance represents a percentage of the state value. The default, 1e-3, means that the computed state is accurate to within 0.1%.

Absolute tolerance is a threshold error value. This tolerance represents the acceptable error as the value of the measured state approaches zero.

The solvers require the error for the

ith state, ei, to satisfy:

The following figure shows a plot of a state and the regions in which the relative tolerance and the absolute tolerance determine the acceptable error.

Absolute Tolerances

Your model has a global absolute tolerance that you can set on the Solver pane of

the Configuration Parameters dialog box. This tolerance applies to all states in the

model. You can specify auto or a real scalar. If you specify

auto (the default), Simulink initially sets the absolute tolerance for each state based on the

relative tolerance. If the relative tolerance is larger 1e-3,

abstol is initialized at 1e-6. However, for

reltol smaller than 1e-3, abstol for the

state is initialized at reltol * 1e-3. As the simulation

progresses, the absolute tolerance for each state resets to the maximum value that

the state has assumed so far, times the relative tolerance for that state. Thus, if

a state changes from 0 to 1 and reltol is 1e-3,

abstol initializes at 1e-6 and by the end of the simulation

reaches 1e-3 also. If a state goes from 0 to 1000, then abstol

changes to 1.

Now, if the state changes from 0 to 1 and reltol is set at

1e-4, then abstol initializes at 1e-7 and by the end of the

simulation reaches a value of 1e-4.

If the computed initial value for the absolute tolerance is not suitable, you can

determine an appropriate value yourself. You might have to run a simulation more

than once to determine an appropriate value for the absolute tolerance. You can also

specify if the absolute tolerance should adapt similarly to its

auto setting by enabling or disabling the

AutoScaleAbsTol parameter. For more information, see Auto scale absolute tolerance.

Several blocks allow you to specify absolute tolerance values for solving the model states that they compute or that determine their output:

The absolute tolerance values that you specify for these blocks override the global settings in the Configuration Parameters dialog box. You might want to override the global setting if, for example, the global setting does not provide sufficient error control for all of your model states because they vary widely in magnitude. You can set the block absolute tolerance to:

auto–

1(same asauto)positive scalarreal vector(having a dimension equal to the number of corresponding continuous states in the block)

Tips

If you do choose to set the absolute tolerance, keep in mind that too low of a value causes the solver to take too many steps in the vicinity of near-zero state values. As a result, the simulation is slower.

On the other hand, if you set the absolute tolerance too high, your results can be inaccurate as one or more continuous states in your model approach zero.

Once the simulation is complete, you can verify the accuracy of your results by reducing the absolute tolerance and running the simulation again. If the results of these two simulations are satisfactorily close, then you can feel confident about their accuracy.