Siemens Healthineers Employs Model-Based Design and HDL Generation for Real-Time Surgery Medical Image Processing

DSA Development Accelerated with HDL Code Generation

“Using these tools, we can obtain a hardware-optimized model that can automatically generate HDL code, which eliminates the tedious and time-consuming step of HDL coding and debugging. As a result, our engineers can focus more time and energy on algorithm design and optimization.”

Key Outcomes

- Model-based image processing enabled engineers to explore design alternatives while reducing development time.

- Simulink and Vision HDL Toolbox provided ready-to-use elements that significantly improved modeling efficiency and enabled the generation of production-quality HDL code using HDL Coder.

- HDL Coder bridged the gap between algorithm development and hardware implementation, leading to faster implementation and verification.

Siemens Healthineers is a medical technology company driving global innovation in advanced healthcare screening and diagnostics, including developing imaging products for techniques like digital subtraction angiography (DSA). Physicians use DSA to diagnose and treat vascular conditions, including strokes.

DSA techniques use computer vision to remove bones or other interfering image artifacts and deliver clear, real-time images of the vascular system. However, traditional methods for implementing DSA techniques in hardware, such as manually coding register-transfer level (RTL) code and optimizing for power, performance, and area (PPA) optimizations, can be inefficient. To address this, Siemens Healthineers used Model-Based Design to develop a DSA instrument with a workflow that improves modeling efficiency and bridges the gap between algorithm development and hardware implementation.

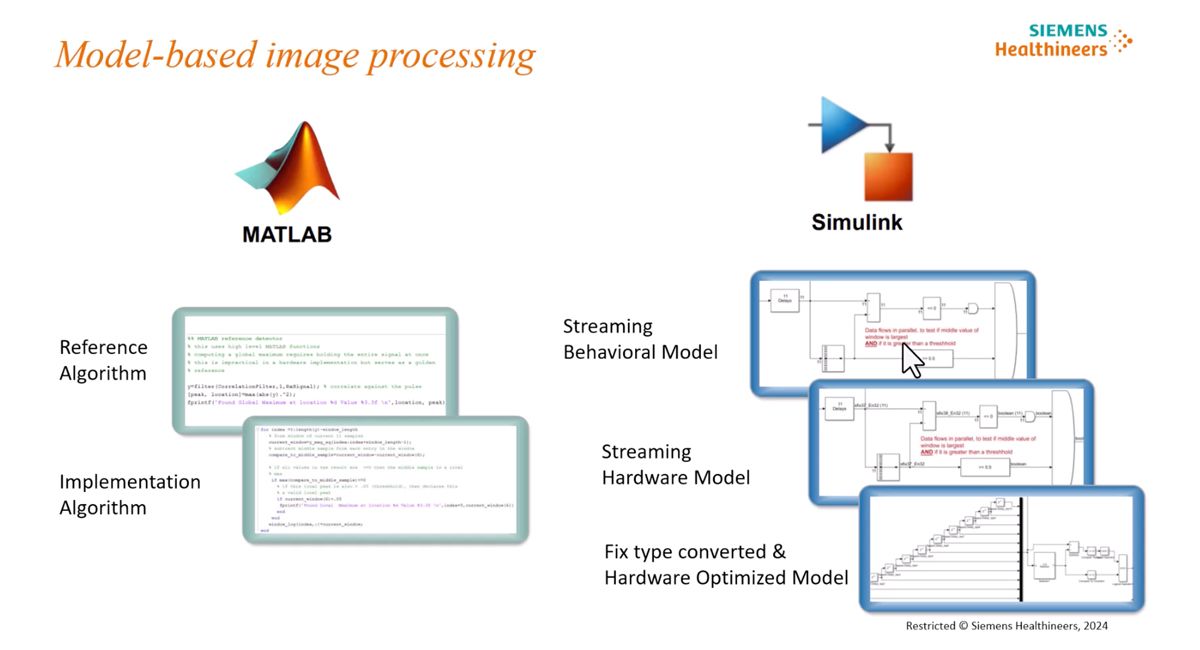

In this project, Siemens Healthineers engineers started with a reference design in MATLAB® code that was used to ensure functional correctness while minimizing design risk. This reference algorithm was then converted into a system-level model in Simulink®. Engineers then used Vision HDL Toolbox™ and Stateflow® to build a robust, hardware-ready model. HDL Coder™ was used to generate production-quality RTL code, and HDL Verifier™ was used to verify the RTL code against the Simulink source model using cosimulation with their RTL simulator. These products eliminated the manual coding effort for engineers and allowed them to have more involvement in implementing the imaging algorithms.

By adopting Model-Based Design, Siemens Healthineers improved its DSA product development from manual coding to an automated workflow using MATLAB and Simulink.