Create and Analyze Random Schedules for a Model Using the Schedule Editor API

This example uses the Schedule Editor API to perform operations on the schedule. Then it uses a function to generate random schedules and analyze them in Simulation Data Inspector

Open the Model and Get the Schedule Object

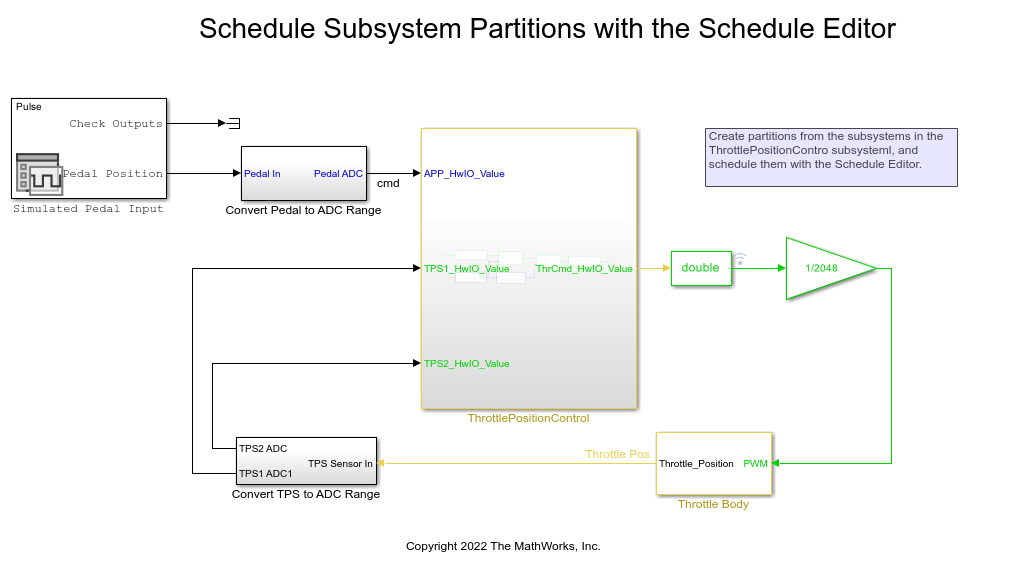

Open a model of a Throttle Position Control system and use get_param to obtain the simulink.schedule.OrderedSchedule object. This object contains the current schedule.

model = 'ScheduleEditorAPIWithSubsystemPartitions'; open_system(model); schedule = get_param(model,'Schedule')

schedule =

OrderedSchedule with properties:

Order: [7×3 table]

RateSections: [3×1 simulink.schedule.RateSection]

Events: [0×1 simulink.schedule.Event]

Description: ''

Examine the Schedule Object

The schedule object has an Order property that contains the execution order of the partitions in the model. The Order property displays a table that contains partition names, their index, type, and their trigger.

schedule.Order

ans =

7×3 table

Index Type Trigger

_____ ________ _______

Cont 1 Periodic "0"

TPSSecondaryRun5ms 2 Periodic "0.005"

MonitorRun5ms 3 Periodic "0.005"

ControllerRun5ms 4 Periodic "0.005"

ActuatorRun5ms 5 Periodic "0.005"

APPSnsrRun 6 Periodic "0.01"

TPSPrimaryRun10ms 7 Periodic "0.01"

Use the index variable in the Order table to change the execution order of the model

schedule.Order.Index('ActuatorRun5ms') = 2;

schedule.Order

ans =

7×3 table

Index Type Trigger

_____ ________ _______

Cont 1 Periodic "0"

ActuatorRun5ms 2 Periodic "0.005"

TPSSecondaryRun5ms 3 Periodic "0.005"

MonitorRun5ms 4 Periodic "0.005"

ControllerRun5ms 5 Periodic "0.005"

APPSnsrRun 6 Periodic "0.01"

TPSPrimaryRun10ms 7 Periodic "0.01"

Any moves within the Order property that are made to modify the schedule should result in valid schedule. To perform the schedule modifications and valid moves easier, each partition is grouped with partitions of the same rate in the RateSections property. Each element of the RateSection property contains an order table with partitions of the same rate.

schedule.RateSections(2) schedule.RateSections(2).Order

ans =

RateSection with properties:

Rate: "0.005"

Order: [4×3 table]

ans =

4×3 table

Index Type Trigger

_____ ________ _______

ActuatorRun5ms 2 Periodic "0.005"

TPSSecondaryRun5ms 3 Periodic "0.005"

MonitorRun5ms 4 Periodic "0.005"

ControllerRun5ms 5 Periodic "0.005"

Use the index variable to move the partitions within RateSections.

schedule.RateSections(2).Order.Index('ActuatorRun5ms') = 5;

schedule.Order

ans =

7×3 table

Index Type Trigger

_____ ________ _______

Cont 1 Periodic "0"

TPSSecondaryRun5ms 2 Periodic "0.005"

MonitorRun5ms 3 Periodic "0.005"

ControllerRun5ms 4 Periodic "0.005"

ActuatorRun5ms 5 Periodic "0.005"

APPSnsrRun 6 Periodic "0.01"

TPSPrimaryRun10ms 7 Periodic "0.01"

Create a Function to Generate Random Schedules

In this section, we create three different functions: randomSchedule, generateSimulationInputs and simulateRandomSchedules

randomSchedule function is used to create random schedules by using random permutations of index modifications in the schedule object. Using the Order and the RateSections properties of the schedule object, partitions in the schedules are moved around in different, random combinations. With these randomly created schedules, models are simulated and compared to study the effect of different schedules on simulation. In the function randomSchedule, the input is the model name. Then use get_param to obtain the simulink.schedule.OrderedSchedule object of the model. The schedule object and its properties are used to modify and randomize the schedules. Create a variable firstExecutionOrder for the first rate section of the model. The rateSections(1).ExecutionOrder = [firstExecutionOrder(1,:); reSchedule(firstExecutionOrder(2:end,:))] line of code calls the function reSchedule which creates random permutations of the indexes.

type randomSchedule

function schedule = randomSchedule(model)

% schedule = randomSchedule(model) Produces a

% simulink.schedule.OrderedSchedule that has a randomized permutation

% of the model's original execution order schedule

arguments

model char = bdroot

end

schedule = get_param(model, 'Schedule');

rateSections = schedule.RateSections;

firstOrder = rateSections(1).Order;

% This assumes that the slowest discrete rate is at index 1. This may

% not be the case for all models (ex. JMAAB-B).

rateSections(1).Order = [firstOrder(1,:); reSchedule(firstOrder(2:end,:))];

for i=2:length(rateSections)

rateSections(i).Order = reSchedule(rateSections(i).Order);

end

schedule.RateSections = rateSections;

end

function out = reSchedule(in)

numPartitions = height(in);

in.Index = in.Index(randperm(numPartitions));

out = in;

end

To analyze the effects of different schedules on the model, simulate the model with the different schedules. In this function, create an array of Simulink.SimulationInput objects. Through this array of Simulink.SimulationInput objects, you can apply the schedules to the model with the setModelParameters method of the Simulink.SimulationInput object.

type generateSimulationInputs

function in = generateSimulationInputs(model, numSimulations)

% in = generateSimulationInputs(model, numSimulations) Generates

% numSimulations Simulink.SimulationInput objects each containing a

% different, randomized execution order schedule

arguments

model char = bdroot

numSimulations double = 10

end

in(numSimulations) = Simulink.SimulationInput();

in = in.setModelName(model);

for idx = 1:numSimulations

in(idx) = in(idx).setModelParameter('Schedule', randomSchedule(model));

end

end

In the last function, use the array of Simulink.SimulationInput objects to run multiple simulations. Once the simulations are complete, you can plot the output of all the simulations in Simulation Data Inspector.

type simulateRandomSchedules

function out = simulateRandomSchedules(model, numSimulations)

% out = simulateRandomSchedules(model, numSimulations) Simulates a

% model numSimulations number of times. Each simulation has a

% randomized execution order schedule.

arguments

model char = bdroot

numSimulations double = 10

end

in = generateSimulationInputs(model, numSimulations);

out = sim(in);

plot(out);

end

Execute the Functions

Now run the above functions for the ScheduleEditorAPIWithSubsystemPartitions model. First, use the randomSchedule function to create randomly generated schedules, then, use the generateSimulationInputs function to generate an array of Simulink.SimulationInput objects, and use the simulateRandomSchedule function to simulate the model with different schedules and plot their results for comparison. Let's run simulations with 15 randomly generated schedules.

simulateRandomSchedules(model,15)

[12-Aug-2025 19:14:11] Running simulations... [12-Aug-2025 19:14:24] Completed 1 of 15 simulation runs [12-Aug-2025 19:14:26] Completed 2 of 15 simulation runs [12-Aug-2025 19:14:28] Completed 3 of 15 simulation runs [12-Aug-2025 19:14:31] Completed 4 of 15 simulation runs [12-Aug-2025 19:14:34] Completed 5 of 15 simulation runs [12-Aug-2025 19:14:36] Completed 6 of 15 simulation runs [12-Aug-2025 19:14:38] Completed 7 of 15 simulation runs [12-Aug-2025 19:14:39] Completed 8 of 15 simulation runs [12-Aug-2025 19:14:41] Completed 9 of 15 simulation runs [12-Aug-2025 19:14:43] Completed 10 of 15 simulation runs [12-Aug-2025 19:14:45] Completed 11 of 15 simulation runs [12-Aug-2025 19:14:47] Completed 12 of 15 simulation runs [12-Aug-2025 19:14:49] Completed 13 of 15 simulation runs [12-Aug-2025 19:14:51] Completed 14 of 15 simulation runs [12-Aug-2025 19:14:53] Completed 15 of 15 simulation runs ans = 1x15 Simulink.SimulationOutput array