MI-Partners Develops Nanometer-Precision Sample Positioning Prototype

Creating Ultra-Precise Motion Systems to Support Cutting-Edge Scientific Research

“MATLAB offers a wide set of tools suitable for the development of high-tech systems. This allows us to quickly test complex control algorithms to obtain optimal performance.”

Key Outcomes

- Simulink and Speedgoat enabled rapid control prototyping, allowing engineers to quickly design, simulate, and test algorithms in real time, significantly shortening the development cycle while allowing teams to evaluate multiple design concepts efficiently.

- Simulink model development and real-time execution on Speedgoat ensured a seamless transition from simulation to physical implementation, reducing integration challenges, minimizing errors, and enabling immediate validation of control strategies on actual hardware.

- Simulink supported the development of advanced, high-precision control algorithms essential for applications requiring nanometer-level accuracy while also providing flexibility to iterate and refine these algorithms to optimize performance and adapt to changing requirements.

MI-Partners specializes in developing prototypes for advanced precise positioning devices. This process begins with conducting feasibility studies, which involve efficiently evaluating various design concepts to identify the most promising solutions.

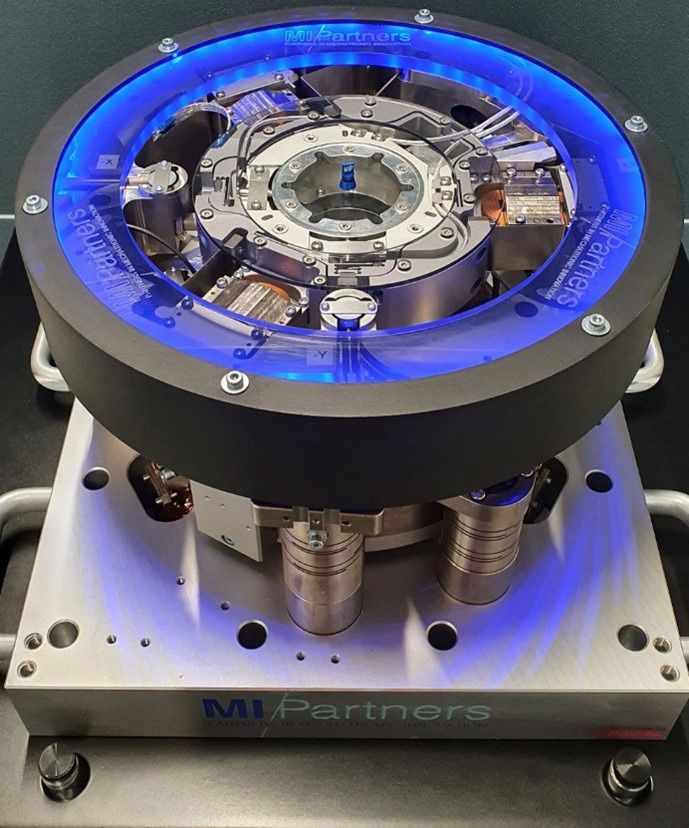

One particular project required MI-Partners to demonstrate that a product sample could be positioned with nanometer-level accuracy within a synchrotron beamline. Synchrotrons evaluate material properties by smashing particles together at very high speeds and studying the makeup of the ones that result from such collisions. Achieving such precise positioning was critical for the customer’s application.

To control and determine the exact location where the sample needed to be placed, MI-Partners used control algorithms designed in Simulink®. The control logic was then converted into executable code and deployed to a real-time target machine in Speedgoat®. Speedgoat then executed the compiled code, performing all necessary calculations and interfacing directly with the system’s actuators and sensors in hard real time.

The physical positioning system was based on a magnetically levitated (MagLev) platform. This platform, actuated by Lorentz force actuators, moved the sample according to the instructions generated by the control algorithms. By following this iterative workflow—designing controllers in Simulink, deploying them to Speedgoat, and testing the MagLev platform—MI-Partners could efficiently evaluate multiple prototype designs and select the optimal solution.